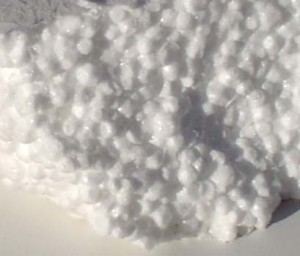

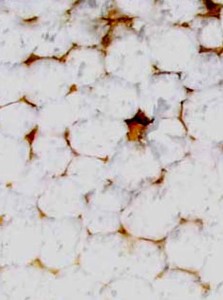

As you can see from the above pictures the various degrees of how water effects EPS foam. EPS is made up of very thin-walled beads, surrounded by open channels (as delineated on the right by assorted scum and salts taken on together with a gulp of water, allowed to stew for a couple of days).

As water enters the core through an injury, or a forgotten vent plug, it spreads throughout the board via these channels. The more water entered and the warmer the board, the faster the spread.

As the water spreads, it brings with it hygroscopic salts, which make removal difficult. It is therefore beneficial to extract the water BEFORE it has a chance to spread. Hours can make a difference on a hot day!

The liquid water in these channels, exposed to elevated temperatures, will turn to vapor. The vapor molecules, being dramatically smaller than the liquid water molecules, are able to permeate the cell membranes.

Once inside the cells, it is an utter pain to extract the water again. Permanent weight gain, as well as permanent propensity to suffer heat-related damage will be the result.